A water valve is a kind of fitting that determines the flow of water, including its regulation, backflow, and direction. Water valves are also used to cut off water access and adjust water pressure in the water supply plants. These valves facilitate the maintenance of water pipes in supply plants. In case of pipeline repairs, the valves of the damaged pipeline can be turned off without shutting the access of other pipelines, hence making the repair convenient. Water valves are commonly used in industries and commercial companies. These valves are integral to the working of wastewater treatment centers, pharmaceutical industries, chemical plants, and automobile industries.

It is of utmost importance that all the water supply facilities ought to use the right valves to ensure a proper and well-maintained water system. Doing so will guarantee smooth water operation with rare needs for maintenance or urgent repairs. This applies to all the industries that use water for their operations, including chemical and pharmaceutical companies. Water valves are used in every industrial manufacturing application, be it regulating the flow of water or purification of the dirty seawater to make it drinkable; Water valves are there.

Water valves can be of many types and shapes depending upon their function and place of installation. Some common types of valves for water treatment include:

Each of the above-listed valves is specific to its function and to its respective places of installation. To know better about which valve fits where we need to take a deep dive into understanding the types of valves along with their uses and specifications.

There are various types of water valves, each specific to its use and function. Some of these have their advantages and disadvantages as well. So, read along, let us understand each type in detail.

Gate valves consist of two parts, namely, handle and gate closure disc. The disc is present inside the valve, which is responsible for turning on and off the valve. When it is off, the water flow is stopped by the gate closure disc, so no fluid or sediments can pass or move from one pipe to another.

Gate valves are designed to be used only for on and off purposes and do not regulate the flow of water or maintain water pressure. Gate valves are well-suited for installation in systems working under high pressure and temperature. These valves are often used in pharmaceutical industries as well as gas and oil extraction companies.

Butterfly valves are used to either stop or regulate the flow of water in a water supply plant. These valves consist of a round disc upon which a shaft is mounted. Its the movement of the disc that is responsible for the opening and closing of the valve. When the disc rotates on the shaft, the valve is either opened or closed. These larger size and budget-friendly valves are installed in wastewater treatment systems because they are lighter and stronger than the other valves.

There are some quirks associated with the use of these valves. For instance, butterfly valves are not designed to deal with blockages caused due to solid sediments obstruction inside the sewerage pipes. These are bound to clog when sludges or solid materials are passed through them.

Check valves are known as non-return valves. These valves are used to prevent the backflow of water into the pipes because no backflow is the indication of a smoothly operating water system. When these valves are turned off in time, they can prevent piping systems from collapsing due to excessive water pressure.

Its operation is simple; a check valve uses the water pressure of forwarding water; the incoming pressure from forward-moving water keeps the valve open, but any backflow will take the pressure force away, thereby closing the valve. To sum it up, the check valve allows the unobstructed flow of water with a maintained pressure, and any drop in pressure will signal the wall to be closed. These valves are the right fit for the industries where prevention of liquid backflow and smooth flow of water in one direction is crucial.

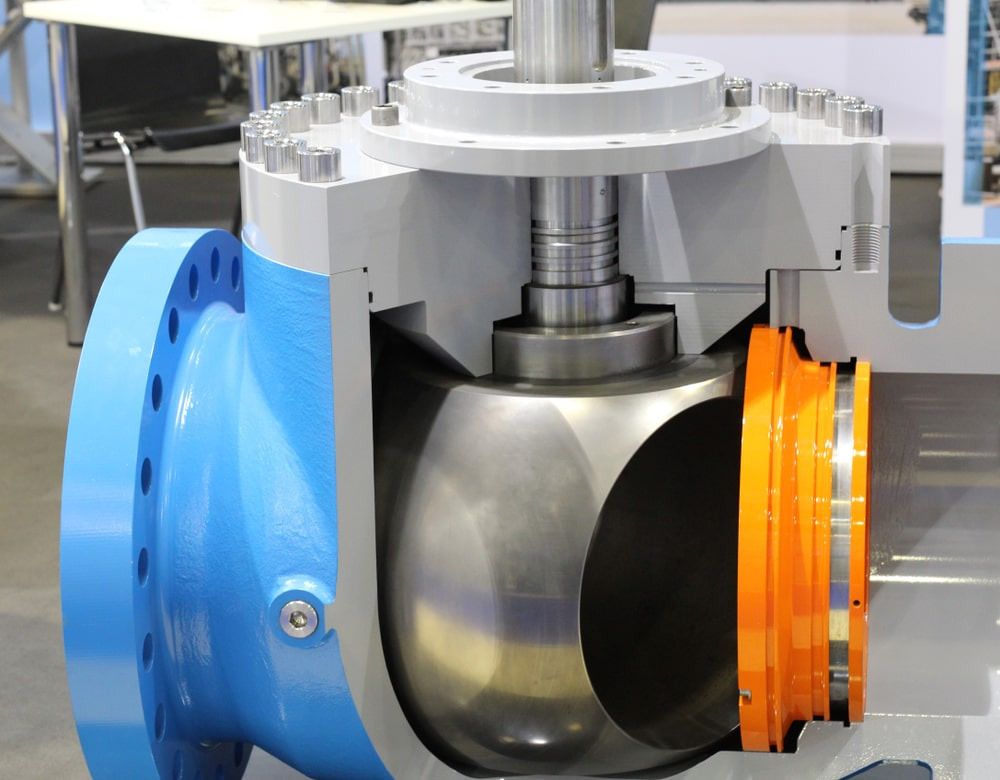

A ball valve consists of a ball placed inside the valve to allow the valve to be opened or closed with only a quarter turn. Besides, it also provides a seal within the valve. These valves are designed to sustain high temperate conditions such as pressure, temperature, and water velocity. Ball valves are mostly installed in the water piping systems of ships. These valves are long-lasting, durable, and easy to install and use. But on the other hand, due to their complexity of structure, they are harder to clean, therefore making them harder to be used in food industries.

Summarily, water supply systems are an integral part of our day-to-day lives because everything we do involves the use of water. Therefore, it is essential to know the ins and outs of water valves so that you can fulfill your water needs without any delay.