The gate valves are generally used for all types of applications, and there suitable for both above ground and underground installation. In plumbing or piping field, it is used to start or stop the flow of liquid, but not for regulating the flow, as the flow path in gate valves gets bigger when you start opening the valve.

The gate valve consists of body, bonnet, disk, stem, hand wheel, and other trim parts. The unique element of a door valve is the fixing of entries by the gate or wedge and seats. A gate or wedge of gate valve moves perpendicular to the flow of the service.

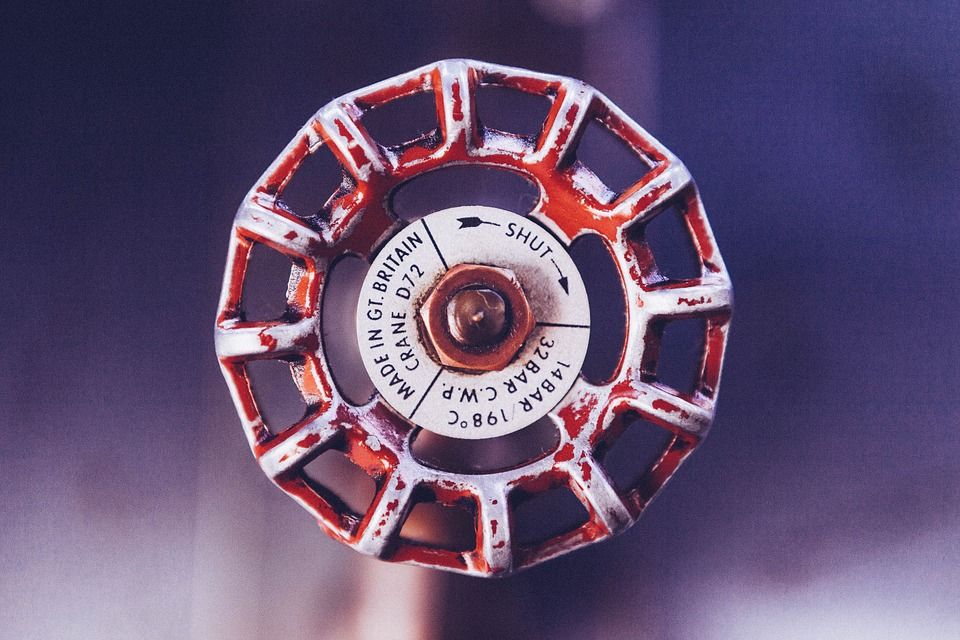

Gate valves are designed either for fully closed or an open service. They are also installed in pipelines as an isolating valve. The gate valves are used by performing clockwise to open (CTO) or clockwise to close (CTC) rotating motion of the stem.

When you move stem in the up position, the valve is open and stem in the down position, the valve gets closed. Partially open gate valves create a lot of noise, vibration, and near shut off.

High fluid velocity cause disk and seat to wear which will result in leakage over a period of time. So, during operation, the gate valves are either completely open or close.

Features

Minor pressure loss when fully open

Contains 360-degree contact between disk and seat

Cannot be used a control valve

The gate valves have either a rising or non-rising stem.

The rising stem basically provides a visual indication of valve position because the stem is attached to the gate in such a way that the gate and stem rise and lower together as the valve is operated. Here, the stem moves up or down while opening and closing.

Whereas, the non-rising stem valves have a pointer threaded onto the upper and of the system to indicate valve position. Since the gate travels up or down the stem, it neither goes higher nor lowers while operating valve. The non-rising stems are used underground or towards the limited vertical space.

Features

No upward stem movement

Insider screw valve

The gate valves are required when a free bore is needed or in case of minimum pressure loss. When the gate valve is fully open, then it doesnt contain any obstruction in the flow path which results in a low-pressure loss, this design enables to use a pipe-cleaning pig.

The gate valve is a multi-turn valve implying that the activity of the valve is finished by methods for a strung stem. As the valve needs to divert various occasions to go from open to shut position, the moderate activity then also anticipates water pound impacts.

There are two types of gate valves; the wedge-shaped, and parallel one. The wedge-shaped gate valves consist of two inclined seats and slight incompatible inclined gate

While the latter one uses a flat gate between two parallel seats, a prominent sort is the blade gate valve outlined with a sharp edge on the base of the door.

The metal-seated gate valve was introduced before a resilient gate valve was introduced in the market. The angular sealing device and conical wedge design of a metal seated wedge need pressure in the valve bottom to ensure a tight enclosure. With this, pebbles and sand are also embedded in the bore.

The pipe system wont be impurity free no matter how thoroughly the pipe has been flushed upon installation or repair. This is how any metal wedge will finally lose its ability to become drop-tight.

The by-pass valves are widely used for three reasons;

To enable the pipeline differential strain to be adjusted, bringing down the torque prerequisite of the valve and allow a small-time task

With the principle valve shut and the by-pass open, a nonstop stream is permitted, escaping conceivable stagnation

These were a few basic chunks of information regarding gate valves which you must know and learn before you approach any gate valve manufacturers for your next project.